Threading parts is an essential element in metalwork. Manufacturers should not overlook the importance of using machining thread in their operations. There is a wide variety of connectors and fittings available in the global market, making it increasingly difficult to identify the right threads for specific applications.

To maximize profits, it is important to explore the various threading technologies available. This article provides a basic guide to machining threading.

Thread Machining in Part Manufacturing

A thread is a continuous, helical ridge with an even section on the surface of either a cylinder or a cone. It can be seen, either internally, on a nut, or externally, on a screw or a bolt.

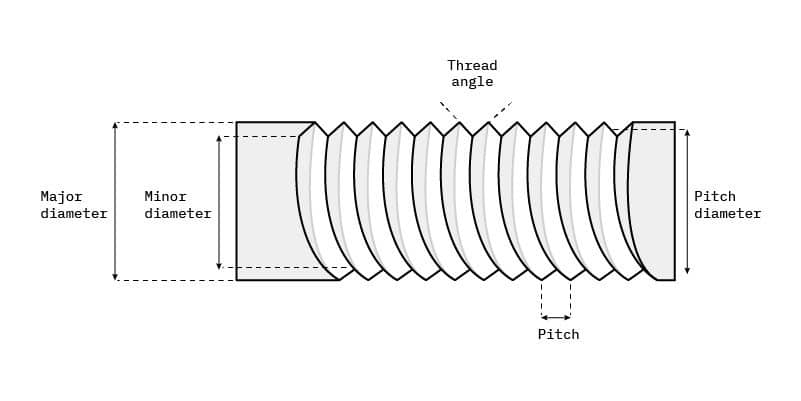

Its primary purpose is to form a link between two objects, like the top and the lid of a water bottle, to create a seal that prevents liquids from escaping. When two parts are connected in this manner, they can transmit motion and gain mechanical advantages. In machining threads, it is important to understand the following terms:

- Flank: The flank is the section that connects the crest to the root and is in an axial plane.

- Root: The root is located at the bottom of the threads, and is the surface joining the flanks of adjacent thread forms.

- Pitch: The measurement of the distance between areas of corresponding threads along a parallel line is called the pitch. The theoretical diameter of a cylinder or cone is referred to as the pitch diameter.

- Crest: The crest of a thread is the highest point of the profile, the area farthest away from the cone or cylinder where the thread projects.

- Helix angle: Helix angle is the angle created by a straight thread in relation to the thread axis. If the thread is tapered, the helix angle is determined by the conical spiral area of the thread.

Types of Machining Threads

Different standards exist when it comes to categorizing threads. Generally, fasteners are either spaced threads or machine screw threads, while the most common are unified and metric.

Here, we’ll discuss the two main types of threads: internal and external threads.

Internal Threads

Internal threads, referred to as female threads, are produced through machining with either a single-lip threading tool or a traditional threading cap, and the process takes place on concave surfaces only. The necessity of an internal thread arises when the workpiece requires the insertion of screws, for which purpose machinists use either hand taps or machine taps.

External Threads

Also recognized as the screw thread, it’s used in screws, bolts, studs, and plug gages, can be created with a lathe, which is a highly efficient method. Alternatively, a round die can be situated in a fixed die stock and used to produce the external thread manually. Moreover, hexagonal and square dies are also available, and often used when interlocking is necessary.

Learn more about our CNC Screw Machining Services

Ways To Improve Efficiency of Thread Manufacturing

1. Call Out Thread Depths on Blind Holes

Blind holes are holes that lack the ability to go through the entire wall thickness of a component. If you request a thread on a blind hole, it is always necessary to note the depth of the thread.

2. Adopt Industry Standards

Keeping the industry standards for threading can be very beneficial for you in regards to both time and cost when it comes to the manufacturing process. If you can find a pre-existing solution, it is often more efficient than creating one yourself. It’s recommended that utilize the standard types and series as much as possible.

NPT and BSP are two types of threads that are also used commonly in certain regions; however, overseas suppliers often have difficulty with this without having special expertise. Thus, it is recommended to always make design decisions that will allow for the largest number of manufacturers to be able to supply the product.

- Common sizes: UN list, Metric list

- Common series: UN (UNC and UNF), and Metric (M).

3. Be Aware of the Hole Sizes

When producing parts that include threaded components, an occurrence is that the specified thread size does not seem to correlate with the size of the hole it is intended to fit. This can be a problem as it creates uncertainty over whether the problem lies with the thread size or the diameter of the hole. Thus, you must take caution to not make assumptions, and this confusion ultimately can lead to a substantial delay in production time, taking at least one to two days to resolve.

Types of Thread Machining/Thread Manufacturing Methods

There are various approaches to producing screw threads, with the most suitable technique being determined depending on a range of factors such as time constraints, budget, the degree of exactness required (or not required), the available equipment, the cost of the threaded product (which depends on the amount of parts to be created), etc.

Many methods of creating threads have been devised, with all the options and considerations being discussed below in detail.

Subtractive methods

1.Thread cutting

Thread cutting is employed for a variety of purposes, such as when full thread depth is required, the quantity is small, the blank is not very precise, threading up to a shoulder is necessary, a tapered thread needs to be threaded, or the material is fragile.

Thread milling

Thread milling is a process that utilizes a rotating milling cutter to create helical toolpaths, something formerly arranged mechanically but that is now possible through the widespread use of CNC machines. This method of threading is faster, with less risk of tool breakage, and can be used to create both left- and right-handed threads with the same tool. Additionally, it is a preferable technique for large and awkward workpieces that would otherwise require them to be set up for rotation. Thread milling uses either solid or indexable tooling:

- Solid cutters are generally limited to holes larger than 6 mm (0.24 in). Solid multiple-form thread cutting tools may look like taps, but they don’t have a backtaper or lead-in chamfer, allowing for the threads to be formed within one pitch length of the bottom of a blind hole.

- Indexable internal thread cutting tools can be used for holes larger than 12 mm (0.47 in). When the insert wears out, it can be easily and more cost-effectively replaced. However, the cycle time is generally longer than with solid tools.

Thread milling offers an advantage over tapping, which will not produce a complete thread profile until the third thread.

Learn more about our CNC Milling Capabilities

Thrilling

The process of threading and drilling internal threads by means of a specialized cutting tool on a CNC mill is an exciting experience. This cutting tool includes a tip shaped like a drill or center-cutting endmill and a body with a thread-shaped form, as well as a countersink cutter form near the shank. Initially, the tool is used to plunge and drill the hole, and then the thread is circularly interpolated using the multiple-form cutter.

By using this method, the drilling, chamfering and threading of a hole can be completed in one cycle, eliminating the need for a separate tool, tool holder and tool change. However, this process is limited to holes of a depth no greater than three times the diameter of the tool.

Learn more about our CNC Drilling Capabilities

Single-point threading

Single-point threading is a process which uses a single-point tool to create a threaded shape on a cylinder or cone, either externally or internally. It requires the precise rotation of the workpiece to determine the lead of the thread.

Common machines used for this process today are engine lathes and CNC lathes. CNC machines are able to track the relationship of the tool and spindle position, making it quick and easy to program.

Although all threading could be done with a single-point tool, other methods such as die threading, thread rolling, and tapping are usually used when a high volume of threads is needed or for cost efficiency. However, single-point threading may be favored in certain circumstances, such as if a special thread is needed or if there is a need for high concentricity with other part features machined at the same time.

Helical broaching (Punch Tap)

Helical broaching was developed to reduce the toolpath of tapping. This process, which looks similar to traditional tapping but with a faster movement, requires a specific tool geometry and toolpath to quickly insert and retract the thread in a single half-turn, thus reducing cycle time and energy consumption.

This method is cost-effective for any holes that can safely accommodate the two small fast-helix grooves it leaves behind, which is applicable in many different applications.

Taps and dies

A typical approach of threading is cutting with taps and dies. In comparison to drill bits, hand taps do not automatically get rid of the chips that they generate. A hand tap does not have the capability to cut its threads in a single rotation, as this generates lengthy chips which shortly jam the tap and could cause it to fracture (an issue known as “crowding”).

Therefore, during manual thread cutting, it is recommended to cut the threads by 1/2 to 2/3 of a revolution (180-240°rotation) followed by reversing the tap for approximately 1/6 of a revolution (60°) until the chips are broken by the back edges of the cutters. It might be required to take out the tap from the hole periodically to remove the chips, particularly when threading a blind hole.

For continuous tapping operations, specialized spiral points or “gun” taps are used to expel the chips and prevent crowding.

2.Thread grinding

Thread grinding is a machining process used to form precise threads on hard materials. It is done on a grinding machine using specially dressed grinding wheels, which match the shape of the threads.

There are three types of thread grinding:

- Center-type grinding with axial feed: Center-type grinding with an axial feed is the most common, and is similar to cutting threads on a lathe.

- Center-type infeed thread grinding: A grinding wheel with multiple ribs is used, and for centerless thread grinding, blanks are hopper-fed to the grinding wheels.

- Centerless thread grinding: The production rate of centerless thread grinding is usually 60 to 70 pieces per minute for a 0.5 in (13 mm) long set screw.

3.Thread lapping

Usually, thread cutting or grinding will be implemented afterward with thread lapping in order to attain the most accurate precision and surface finish possible. This is a toolroom procedure used when the highest degree of accuracy is essential, normally only included for the leadscrews or ballscrews of sophisticated machine tools.

4.Threading with EDM

Internally threaded parts can be formed by electrical discharge machining (EDM) into tough materials with the use of a sinker type machine.

Deformative or transformative methods

Thread casting and molding

Threads in metal parts can be directly formed by the geometry of the mold cavity in the mold or die, where the material is heated to a liquid or mixed with a liquid that will either dry or cure. The threads may then be finished with machining or left in the as-cast state, depending on the application.

This is the principal method of thread generation in manufacturing today with the moldmakers needing to be precise for millions of cycles. Common examples of molded plastic threads are soda bottles, while cable glands are common examples of die-cast threads.

Learn more about our Custom Die Casting Services

Thread forming and rolling

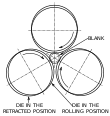

Thread forming and thread rolling are techniques used to form screws instead of using cutting techniques. A thread rolling die is used to press a blank and form the threads. This process can be used for mass production since it is capable of producing up to one piece per second. Additionally, less material is used since the blank sizes can be smaller than those for cutting threads; there is a potential material savings of 15-20%.

Furthermore, rolled threads can be easily identified since they have a larger diameter than the blank rod from which they are made. Unless faced off, the end threads of rolled fasteners have a cupped end since the surplus material collapses evenly over the end of the blank.

| Description | Image | Application |

| Planetary dies(planetary roller) |  | Drive screws, high volumes screws, and sheet metal screws |

| Flat dies (flat roller) |  | Machine, tapping and wood screws |

| Cylindrical in-feed 2 dies |  | Threaded bar stock, large or balanced screws |

| Cylindrical in-feed 3 dies |  | Threaded bar stock, tube fitting, spark plugs |

| Thread diameter (in.) | Planetary (pieces/min) | Flat dies (pieces/min) | Cylindrical (pieces/min) |

| 1/8 | 450 to 2000 | 40 to 500 | 75 to 300 |

| 1/4 | 250 to 1200 | 40 to 400 | 60 to 150 |

| 1/2 | 100 to 400 | 25 to 90 | 50 to 100 |

| 3/4 | – | 20 to 60 | 5 to 10 |

| 1 | – | 15 to 50 | 1 to 50 |

Additive methods

3D printing, also known as additive manufacturing, is a process that is beginning to gain traction in commercialization, including:

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- MultiJet Fusion (MJF)

- Stereolithography (SLA)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Binder Jetting

While these methods are often limited in the material properties they can create and the surface finishes they can produce, they are becoming increasingly capable over time. As an example of the success of additive manufacturing for threaded parts, SLS and SLM have been used to create threaded titanium implants for use in dental implants and bone screws.

Learn more about our 3D Printing Services

Combinations of Different Methods

Combining multiple techniques such as subtractive, additive, transformative, or deformative methods into a new form are frequently used in combination to achieve desirable results.

This type of manufacturing can also be referred to as rapid prototyping, desktop manufacturing, direct manufacturing, direct digital manufacturing, digital fabrication, instant manufacturing, or on-demand manufacturing.

Learn more about our Rapid Prototyping Services

Tips for Machining Thread

Successfully using thread-cutting technology requires more than just knowing how to cut threads. Here are a few design tips to help you maximize the benefits of thread-cutting technology:

- Adding a chamfer to external thread ends will ensure a better finish.

- The starting point of a thread must have a flat surface that is aligned to the thread’s central axis.

- For internal threads, countersink can be used to provide a better finish.

- Tubular parts must have increased wall thickness when undergoing thread forming or thread cutting due to the pressure.

- Using a standard thread size is more cost-effective than using a unique thread size.

- Lower-height threads are preferable over higher-height threads when there are no specifications for the thread size.

Conclusion

The successful execution of creating parts with superior quality necessitates an in-depth comprehension of the manufacturing techniques. Thread machining, an essential element of the manufacturing process, may be challenging as it requires specialized skills and advanced equipment. Why not outsource your manufacturing needs with a reliable supplier? Runsom Precision is the perfect choice for precision machining for threads.

At Runsom Precision, our team of engineers have an extensive amount of CNC project knowledge and expertise acquired over a decade of industry experience. We prioritize our client’s needs to ensure that our threaded parts will match up with their expectations and hold up to extended use, while also providing quality services at economical prices.

If you have any questions or want to upload your design files to get an instant quote, don’t hesitate to contact us through email.

Other Articles You May be Interested in: