CNC machining is one of the top-notch technologies in the manufacturing sector. In the past, milling was the most preferable manufacturing process when talking about metalworking. However, in the past few decades, CNC machining has taken its place. There are unnumbered benefits of using this technology, such as minimum human error, and the speed of operations has improved tremendously.

CNC machining is a completely automated process and is equipped with several other benefits as well. Yet, its cost-effective factor is one of the most attractive among all. Here’s what you need to know about CNC machining and how much it may cost you.

What Are CNC Milling and CNC Machining?

Computer Numerical Control (CNC) milling is one of the latest technologies that use a rotary cutter to remove material from metal bars and give it the shape of a workpiece, it is one of the most valuable subtractive manufacturing technologies in the market. Moreover, it is also essential to know what cnc machining technology is if you are entering the manufacturing industry.

The main goal of CNC milling is to create the intended part from the material through the cutting process. During this process, the speed and pressure of the cutter play a pivotal role in the overall results.

However, CNC machining and CNC milling are two different terms. One of the main differences is that CNC machining also includes EDM cutting and CNC drilling. It is surely a valuable technology as there are several applications of CNC machining in the medical parts industry as well.

Factors to Consider for the Calculation of CNC Machining Cost

CNC machining cost usually depends on these factors:

CNC Machine Cost

The type of machine is one of the most important factors when it comes to CNC machining cost. However, when it comes to CNC, there are only two types of machines that are usually used for the manufacturing of parts. The multi-axis and 3-axis machines. The cost of the machine you will need to buy is affected by the speed, power, and even the weight of the machine.

The CNC machining cost is mostly calculated hourly and $40 is the approximate cost of 3-axis CNC machining. Moreover, it’s $75 to $125 per hour for CNC multi-axis machines. As there is continuous involvement of complexity in the procedures, the cost is usually high, and the increase in axis is said to increase the price as well.

Labor

It’s evident that the use of CNC machining has reduced the number of laborers required for conducting the operations. Manual machines require an extensive amount of laborers to take part in the manufacturing process. However, the main cost that you have to pay is the person who is responsible for designing the 3D CAD design model, it is done to increase the complexity of the product that is being designed.

However, if you increase the number of parts you need per hour, or increase the hours of CNC machining, it will affect the cost for sure. Another extra cost can be the labor who is tasked to assemble or give the finishing touch to the parts that are manufactured, and if the part is being delivered to the client, more labor cost is added here.

Time

There’s no denying the fact that time is money, the more hours you add up to the machining process, the overall bill will increase. Sometimes the machining time is extended due to excessive work that is required, in such cases, the machining cost is affected. Yet, the good part is that software such as 3D CAD design is capable of telling the estimated time needed to complete the project, so you won’t have to stress about that. Moreover, complex tasks take a longer time to be completed.

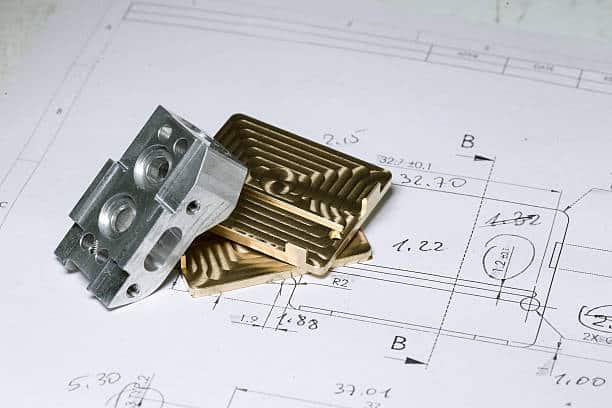

Material Cost

It’s hard to ignore the material cost when it comes to calculating CNC machining costs. As the price of the final product is also dependent on the type of material used, the material cost has a vital role to play in the overall cost. Sometimes, the demand is for plastic parts or metal parts. If the need is for plastic parts, the price is relatively lower, as plastic isn’t long-lasting or less durable. However, if it’s about stainless steel, the price would certainly jump as steel is expensive and durable.

Usually, the required raw material is more as CNC machines strip off the material from these solid blocks to create complex parts. The price of the material is calculated per block, whether it is steel, brass, or aluminum. Yet, aluminum is one of the most demanded materials due to its tremendous price and function. Brass and stainless steel have a higher press but less machinability. Moreover, if any special tool is manufactured using titanium alloy, the price would skyrocket as it is super expensive, and would heavily impact the overall CNC machining price. The cheapest material used in this process is mostly plastic.

Quantity

The quantity of the products required is as important as other factors in terms of determining the CNC machining cost. The cost of the final product is also affected by the quantity ordered by the client. If the volume of the order is increased, the overall cost needed for CNC machining will also climb up. However, there are chances that the cost per part will come down, as manufacturing parts in bulk is much more cost-effective than making lesser parts. This is the reason many clients prefer giving big orders once rather than ordering several times and paying higher prices.

Others

- Surface Finish

Surface finishes enhance the appearance and durability of CNC machined parts in harsh conditions. However, they will add to the machining costs. - Tooling

Custom CNC fabrications might necessitate the machine shop to buy specific tool bits for its manufacturing process. You may need to cover part of the machine costs because the tool bits could become worn out during creation, especially if the raw material is very hard.

Tips to Reduce CNC Machining Cost

If you are planning to minimize CNC machining costs, here are some tips that you should consider:

Change in Material

CNC machining cost is heavily impacted by the type of material you prefer. Considering the price of the material is certainly important. Not only the price, but the machinability of the material is also an essential factor to keep in mind. You can’t invest heavily in material with the least levels of machinability. The machining time is also affected by the machinability of the material used. If you buy expensive material with less machinability, it will increase the hours needed to manufacture the product, ultimately increasing the CNC machining cost.

Increase Production Volume

The manufacturing cost per part is tremendously decreased with the increase in the production volume, because the fixed cost needed to conduct the operations is divided into a higher number of parts, ultimately benefiting the manufacturer. The design cost is decreased when you are planning for large production. A single design blueprint can be used for hundreds or even thousands of final parts needed by the client. The higher the demand by the client in terms of volume, the lesser cost you will have to bear.

Design Complexity

Complex designs tend to fetch higher costs from your pocket. As the design cost increases, the overall CNC machining cost is influenced. In some cases, highly complex designs demand CNC milling machines with extra axes, and the more axes you use, the higher the price. Complex designs are known for impacting prices a lot.

Sometimes, complex designs are even divided into further designs to make the procedure simpler. It is possible to control the increasing CNC machining price by milling simpler designs using 3-axis CNC machines and later assembling them to create the final design demanded by the client. It is one of the most effective ways to reduce costs.

This guide provides some useful tips to minimize the complexity of your design and then helps you to save your project costs. Read it to find the answers: Design Tips for Minimizing CNC Machining Cost

Fewer Finishes

Sometimes in need of better quality edges, CNC machines spend a lot of time giving the best shapes to the edges of the final part. When multiple finishes are made, it demands more labor, tools, and hours. In this way, the price is increased heavily. Many parts are given a secondary finishing process that creates a hike in CNC machining cost, but to tackle this issue, it is best to consider the final CNC milled product as the finished product, as it will save a lot of costs. There are many finishing processes, such as heat treatments, coatings, and much more, that you can choose to avoid.

Outsourcing

Outsourcing projects to CNC machining companies can minimize costs, however, companies in developed countries are expensive. In comparison, Chinese companies are much cheaper and offer the same quality. For example, in Europe, 3-axis machines cost $35 to $40 per hour and multi-axis machines cost $75 to $120 per hour, whereas Runsom in China offers 3-axis machines for $8 to $10 per hour and multi-axis machines for $30 per hour.

Conclusion

CNC machines are some of the most versatile and demanding technologies in the market. They are proven to increase scalability when it comes to manufacturing complex parts. However, you need to utilize time and cost properly to get the best out of this technology. CNC machines give higher workplace safety and have little human error.

Provide Best CNC Machining Solution for Your Projects – Runsom

Are you looking for top quality CNC products at an affordable price? Or perhaps you’re new to the CNC machining process and need a reliable company? At Runsom, we have the perfect CNC machining solutions for you. Our quoting system is mature and developed well, as all you need to do is to submit your files online in several simple steps. We’ll review your design within 12 hours and provide feedback.

Other Articles You May be Interested in: