Bolts, also referred to as fasteners, are the components used to hold two objects tightly together. They come in a broad variety of different grades related to tensile strength. When selecting the exact bolt for an application, there are certain things to consider, such as size, shape, length, thread type, material, and grade. All these factors have been discussed quite extensively except for grades. However, the grades of bolts are a crucial factor that shouldn’t be ignored. In this article, we’ll offer more details on different grades of bolts, how they’re categorized, and some of their uses to help you have an idea about what grade of bolts is best suited for your projects.

Bolt Grades And Strength Chart

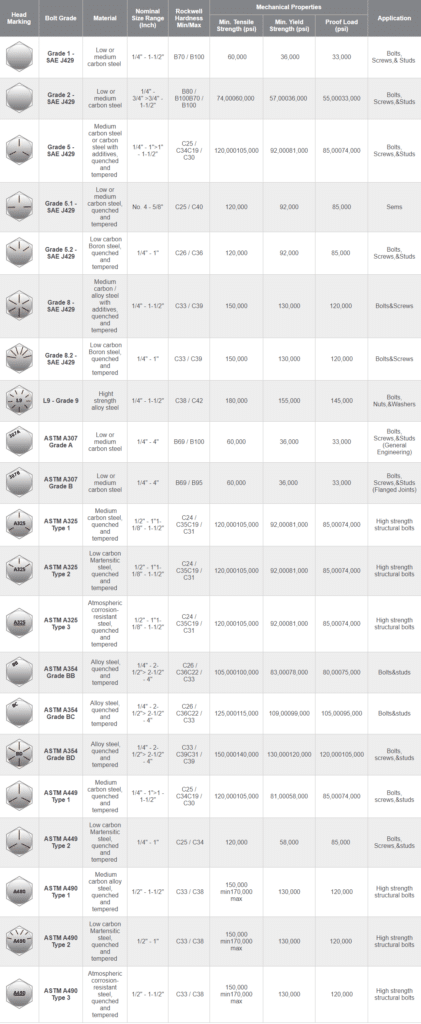

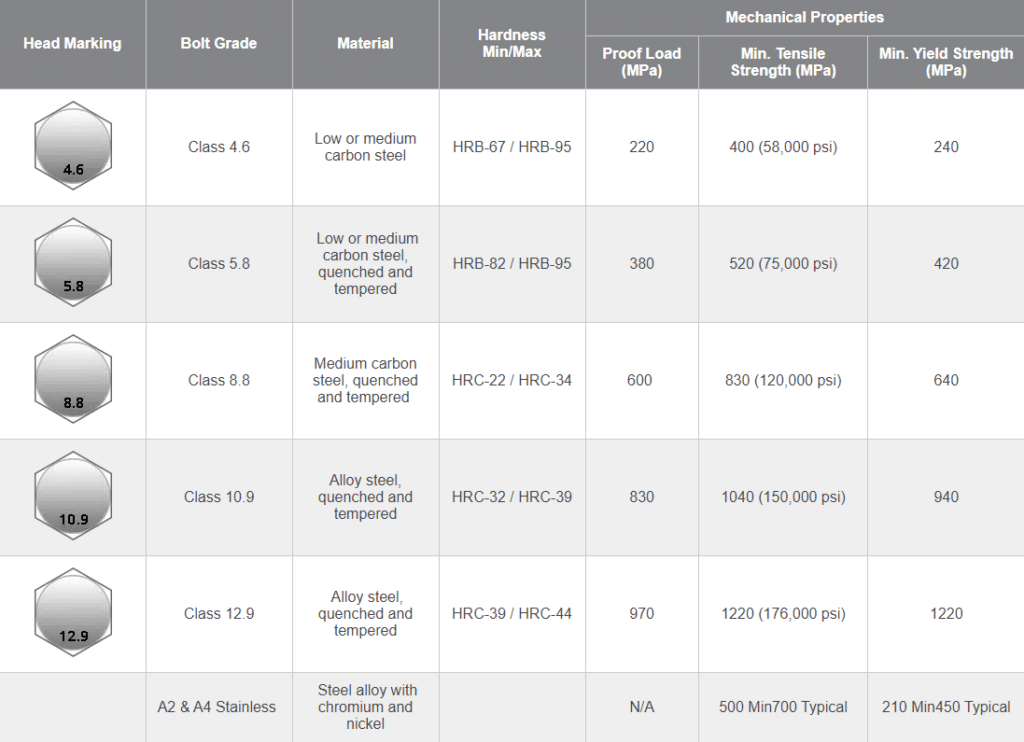

Here, we offer a chart with different grades of bolts and their mechanical properties. And the image in the chart can also help to exhibit the grades of bolts with the identification marks on the bolt’s head as well as the hardness and strength of common grade bolts.

Note that bolt heads may also contain the manufacturer’s identification stamp, especially for high-strength bolts.

Bolt Grades & Strength Chart – Imperial Steel Bolts

Bolt Grades & Strength Chart – Metric Steel Bolts

Note:

Tensile Strength: A measure of the maximum stress a material can withstand while being stretched or pulled before failing. It is also known as ultimate strength.

Yield Strength: A measure of the stress at which a material begins to deform plastically. It is also known as the elastic limit or yield point. It is determined by performing a tensile test on a sample of the material.

Proof Load: A specified test load applied to a component to ensure that it can withstand an expected maximum load. It is often used to test components with static loads such as bolts and screws.

1MPa = 1N/mm2 = 145 pounds/inch2

What Are Bolt Grades & Bolt Grades Chart?

Bolt grades refer to the strength and durability of a bolt, which is typically determined by the material it is made of. The grade of bolts is stamped on a bolt head as a marking that indicates the type of material the bolt is made of and its strength rating. For instance, Grade 2 bolts are made of low-carbon steel and are the most common type of bolt used in construction. Grade 5 bolts are made of medium-carbon steel and are stronger than Grade 2 bolts, while Grade 8 bolts are made of high-carbon steel and are the strongest.

The bolt grades and strength chart outlines the physical and mechanical properties of various grades of bolts. It includes information on the grade of the bolt, the tensile strength, the type of material, and their common applications.

Learn more about Bolts Size Chart

Common Bolt Grades

The most common bolt grades are Grade 2, Grade 5, Grade 8, and Alloy Steel.

- Grade 2 bolts are made of low-carbon steel and are the most common type of bolt. They are relatively strong, but not as strong as Grade 5 or Grade 8 bolts.

- Grade 5 bolts are made of medium-carbon steel and have a tensile strength of at least 120,000 PSI. Grade 8 bolts are made of alloy steel and have a tensile strength of at least 150,000 PSI.

- Alloy steel bolts are very strong and are used in demanding applications such as in automobiles and industrial machinery.

Three Systems of Bolt Grades

There are three main systems of bolt grades: SAE, ASTM, and ISO.

- SAE (Society of Automotive Engineers) grades bolts according to their strength, ranging from grade 2 to grade 8. Grade 2 is the weakest, and grade 8 is the strongest.

- ASTM (American Society for Testing and Materials) grades bolts according to their chemical composition and physical properties, ranging from grade A to grade F. Grade A is the weakest, and grade F is the strongest.

- ISO (International Standards Organization) grades bolts according to their material properties, ranging from class 4.6 to class 12.9. Class 4.6 is the weakest, and class 12.9 is the strongest.

Different Bolts Grades & Their Applications

ASTM A307

- ASTM A307 Grade A consists of low- to medium-strength carbon steel with a minimum strength of 60,000 psi. They’re mostly found in general, non-critical applications and are equivalent to SAE J429 Grade 2 bolts.

- ASTM A307 Grade B consists of medium-strength carbon steel with a strength of 60,000 to 100,000 psi. They are frequently used for flanged joints in piping systems.

SAE J429

- SAE J429 Grade 2 – This grade of bolts is made of low-to-medium strength carbon steel, and is the least strong of the SAE J429 grades, with a strength of 60,000 to 74,000 psi. These bolts are used in non-critical applications and joints as they are cost-effective and not exposed to extreme stress or temperatures.

- SAE J429 Grade 5 – This grade of bolts is made of medium-strength carbon or alloy steel and has a strength between 105,000-120,000 psi. They are popular among heavy machinery and military applications due to their exceptional resistance to stress.

- SAE J429 Grade 8 – This grade of bolts is made of medium-strength carbon or alloy steel and possesses the highest level of strength up to 150,000 psi. As such, it’s an ideal material grade subjected to the harshest, extreme, and rugged conditions, like aerospace engineering, heavy machinery, military, etc.

ISO 898-1

- ISO 898-1 Property Class 8.8 offers medium strength and is comparable to SAE J429 Grade 5. Applications of this class include the military, heavy machinery, and automotive industry.

- ISO 898-1 Property Class 10.9 offers high strength and is comparable to SAE J429 Grade 8. This class is mainly used in the military, heavy machinery, and aerospace.

- ISO 898-1 Property Class 12.9 offers some of the highest available strength. These bolts are used in critical applications like securing engine parts and motor casings and are the strongest bolts made by Wilson-Garner.

Titanium & Stainless Steel Bolt Grades

The three systems of bolts grades we discussed above are comprised of alloy steel or carbon steel. But there are also some bolt grades made of other kinds of materials, such as titanium or stainless steel.

Some common bolt grades made of titanium or stainless steel are listed below:

- Titanium

Grade 2 – Commercial grade with a strength of 50,000 psi

Grade 5 – High strength with a strength of 138,000 psi - Stainless Steel

304 – Commercial grade with a strength of 74,000 psi

316 – Marine grade with a strength of 180,000 psi

Turn On Runsom to Manufacture Your Custom CNC Machined Bolts

By the end of this article, you may understand these grades of bolts better right now. If you still have no idea about which bolt grade is right for your application, feel free to talk to experts at Runsom. Our CNC specialists are happy to help you determine the most suitable type of materials, and then manufacture them exactly to fit your specifications and requirements.

As a manufacturer who provides CNC machining services for global customers for over ten years, Runsom is always keen on assisting every client to solve their problems whether for product designing, manufacturing, or DfM, and offering you a solution that might make effects better for your applications. Get an instant quote online or reach out to us directly today!

Other Articles You May be Interested in: