Back in the day, designers had limited tools at their disposal such as paper and pencils to create part drawings. However, the introduction and implementation of Computer-Aided Design (CAD) software revolutionized the design and production processes of the manufacturing industry. It has become the norm in mechanical design and production as it largely automates the drawing process while improving accuracy.

CAD modeling is eventually integrated with the CNC machining operations, enabling the simulation of the workpiece movement through this manufacturing process. Nowadays, most manufacturers in the design and production industry use 3D CAD as their primary tool. But if you are faced with the decision between 2D and 3D CAD software, this article will help you make an informed choice by presenting the differences between 2D and 3D CAD drawings and guide you toward the ideal solution.

What is 2D CAD?

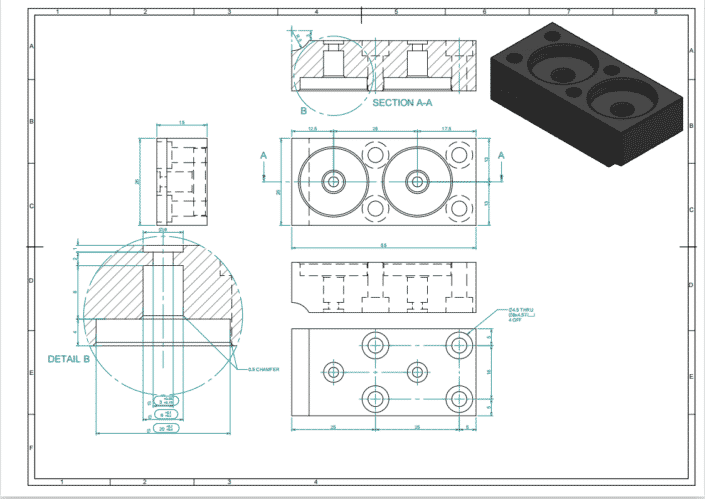

2D CAD (Computer-Aided Design) drawing is a technology that allows designers and engineers to create two-dimensional technical drawings of physical objects or structures.

2D CAD drawing is used in CNC machining to create the design files needed to manufacture parts using CNC machines. The 2D CAD drawing can include precise measurements and dimensions, which are essential for creating accurate CNC programs. CNC machines use these programs to control the cutting tools and produce a part that matches the exact specifications of the CAD drawing. The accuracy and precision provided by 2D CAD drawing software help reduce errors that can result from manual drawings and increase the speed at which parts can be machined. This makes 2D CAD drawing an essential tool for the manufacturing industry where precision and accuracy are highly valued.

The main formats of 2D CAD drawings are:

- DWG (AutoCAD Drawing Database)

- DXF (Drawing Interchange Format)

- DWF (Design Web Format)

What is 3D CAD?

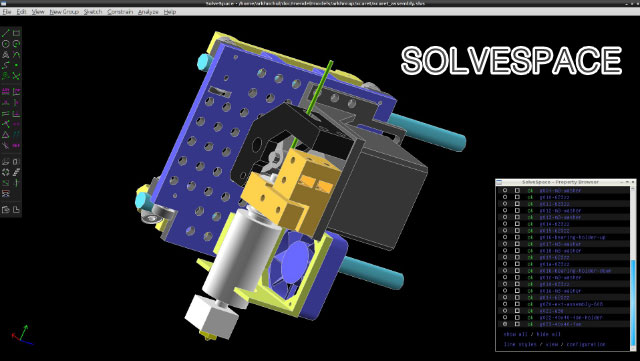

3D CAD drawing is the creation and representation of a 3D model or design using computer-aided design (CAD) software. This type of drawing enables an engineer or designer to create a digital representation of an object with precise dimensions, shapes, and features.

In CNC machining, 3D CAD drawings are used to program the CNC machine to create a physical object. The 3D model is imported into the CNC machine software, and the machine uses the information to guide the cutting tools and create the physical object.

3D CAD drawing benefits CNC machining from:

- Creating complex shapes and designs that would be difficult or impossible to create manually.

- Improving accuracy and precision in manufacturing processes by automating the creation of parts.

- Streamlining the product development process by reducing the time and cost associated with traditional prototyping and production methods.

- Enabling design changes to be easily incorporated into the manufacturing process.

The main file formats for 3D CAD drawings are:

- STL (STereoLithography)

- DWG (Drawing)

- OBJ (Object)

- 3DM (Rhino)

- SLDPRT (SolidWorks Part)

- IPT (Inventor Part)

- SAT (ACIS Solids)

- X_T (Parasolid)

- PRT (NX Part)

CAD in CNC Machining and Manufacturing, and How Does It Work?

CAD modeling is used in CNC machining and manufacturing to create digital designs of parts or products that can then be used by the CNC machines to manufacture them. CAD software allows designers to create complex 2D or 3D designs, make changes easily, and test their designs before they are manufactured.

Once the design is complete, the CAD software can create a computer file that contains all the instructions necessary for the CNC machine to manufacture the product. The file can include information such as the dimensions, materials, tool paths, and cutting speeds needed to make the part.

A Complete Comparison of 2D and 3D CAD

Here, we’ll compare these two technologies from 9 aspects:

1.Definition

2D CAD drawings are created with two-dimensional geometry, using X and Y coordinates to represent the width and height of objects, respectively. These drawings are typically used for floor plans, elevations, and schematics.

3D CAD drawings include additional information for depth, or the Z-axis, to represent the third dimension of objects in space. This creates a more realistic and detailed representation of the object. In 3D CAD, objects can be rotated, viewed from any angle, and even animated to simulate real-world movement.

2.Elements

In terms of their elements, 2D CAD software allows users to create and modify flat and wire-frame drawings with geometry information such as lines, arcs, circles, and other basic shapes that are arranged to represent the design of a product or object on a flat plane.

In contrast, 3D CAD software is designed to build three-dimensional entities such as surfaces, solids, and meshes. Additionally, 3D CAD drawings often include layers, materials, and physical properties such as weight or volume, which can be used to simulate the behavior of the object in various circumstances.

3.Expression

A 2D CAD drawing is a flat representation of an object or image that has two dimensions: width and height. It can be created using software such as AutoCAD or SolidWorks.

A 3D CAD drawing is a three-dimensional model that contains depth in addition to width and height. 3D CAD drawings allow designers to view and manipulate an object from multiple angles and perspectives, giving a more realistic representation of the final product. It can be created using software such as Rhino or Fusion360.

4.Presentation

In a presentation, you may be able to distinguish between 2D and 3D models by looking for cues such as shading, depth of field, and perspective. A 3D CAD drawing will typically have a more realistic, lifelike appearance, while a 2D CAD drawing appears flat and static.

5.Geometric Shape

2D CAD drawings are created using only two coordinates (X and Y), which results in flat geometric shapes such as rectangles, circles, lines, arcs, etc. These shapes are used to represent objects from a top-down or side-to-side view, similar to a blueprint.

On the other hand, 3D CAD drawings are created using three coordinates (X, Y, and Z), which allows for the creation of three-dimensional objects such as cubes, spheres, cones, and more complex shapes. The three-dimensional nature of these objects allows for a more realistic representation of the final product and is particularly useful in engineering and architectural design.

6.Unit of Measurement

2D CAD drawings are typically measured in linear units (e.g. inches, millimeters), which represent height, width, and depth on a flat plane.

3D CAD drawings, on the other hand, are measured in three-dimensional units (e.g. cubic inches, cubic centimeters), which represent length, width, and height in three dimensions.

7.Costs

2D CAD drawings are typically simpler and quicker to create and typically only require basic computer hardware and software, while 3D CAD drawings require more time and expertise to create, as they involve creating a three-dimensional model of the object being designed.

Thus, the cost of 3D CAD drawings is generally higher than that of 2D CAD drawings.

8.Functionality

The main difference in functionality between these two types of software is that 2D CAD software is ideal for creating 2D technical drawings and schematics, while 3D CAD software is better suited for designing complex 3D objects and visualizations.

9.File Compatibility

2D CAD designs typically use file formats such as DWG or DXF, which are 2D file formats that contain only X and Y coordinates. 3D CAD supports file formats such as STL or OBJ, which contain X, Y, and Z coordinates in order to represent the third dimension.

Note that 2D CAD models can sometimes be created or imported into 3D CAD software as a base layer or reference image for creating 3D models. However, 3D CAD files cannot be easily converted or imported into 2D CAD software, as they contain more intricate geometric elements that cannot be easily represented in a 2D drawing.

Advantages of 3D CAD Modeling over 2D

3D CAD technology and software are advantageous in many aspects in contrast to 2D CAD, including:

- Enhanced Visualization: 3D models offer an interactive representation of the design that allows visualization of the product or part from multiple angles. This assists in identifying design flaws and aides in improving the design before the production process starts.

- Simulations and Testing: 3D modeling allows for simulations and testing to be performed within the same software. This means that prototypes can be tested for performance, functionality, and safety before they are physically built, which can save time and money.

- Better Collaboration: 3D modeling software comes with collaborative tools that facilitate better communication between designers, engineers, and manufacturers. This enhances team efficiency and error reduction.

- Accurate Detailing: 3D models present a design with more accuracy and detail than 2D drawings. This allows for better communication of design intent to stakeholders and reduces ambiguity in the manufacturing process.

- Speed and Efficiency: Creating a 3D model is quicker and more efficient than drawing a 2D sketch. Furthermore, making changes to a design is easier, quicker, and more cost-effective in 3D modeling as compared to 2D drafting.

- Improved Design Quality: 3D modeling software offers automated checks and simulations that enable designers to check and correct errors and inconsistencies in their designs before the manufacturing process begins. This increases the design quality of the final product.

Disadvantages of 3D CAD Modeling over 2D

While 3D CAD modeling has many advantages in terms of creating more detailed and realistic designs, it requires more time, effort, and resources compared to 2D CAD modeling.

- Higher Cost: 3D CAD software is typically more expensive than 2D CAD software due to its advanced features and capabilities.

- Difficulty in Learning: 3D modeling requires knowledge of not only line and shape but also depth and volume, so it’s generally more difficult to learn.

- Processing Power: 3D CAD modeling requires more processing power for rendering compared to 2D modeling, which can be a bottleneck to work efficiently.

Conclusion

Here, we have discussed the difference between 2D CAD drafting and 3D CAD modeling, their benefits and drawbacks, and their functional features. While 2D is suitable for technical purposes, 3D offers easier visualization, better marketing, and easier error correction. Ultimately, the choice depends on the specific requirements of your CNC machining projects.

CAD Drafting and Programming Expert in CNC Manufacturing – Runsom Precision

Runsom Precision has extensive experience of over ten years in CNC machining and owns a dedicated team of highly skilled engineering technicians and machinists with a profound understanding of 3D CAD drawing and CNC programming technologies to assist you to find the most suitable solution for your projects. Request an instant quote right now!

Other Articles You May be Interested in: