The metals copper and brass belong to the group of metals known as “red metals” due to their reddish hue. Copper is pure, but brass is an alloy of copper and zinc. These metals exhibit distinctive properties that make them advantageous for usage in sheet metal fabrication and the CNC machining process.

This article offers detailed insights into each of these two metals, including their available grades, applications, and tips for selecting one over the other for a particular application. Additionally, it especially highlights their distinctiveness concerning properties, conductivity, formability, strength, appearance and cost.

About Brass

The alloy brass consists of copper and zinc, and the relative proportions can be adjusted to yield different colors and chemical, physical, and electrical properties. However, typically copper comprises the greater proportion.

Brass, with its bright and lustrous gold-like hue, has long been a preferred material and is still popularly used for making drawer pulls and doorknobs. Additionally, brass has been utilized extensively for sculpting and creating utensils due to its low melting point, malleability (using both manual tools and modern milling and turning machines), rigidity, and excellent thermal and electrical conductivity. The color of brass with higher copper content is more golden and softer, while brasses with lower copper content and more zinc are more silvery and harder.

Properties of Brass

Brass, a copper alloy, shares many common properties with copper. Nevertheless, it has some unique characteristics that differentiate it from pure copper and other copper alloys:

- Brass is more likely to develop stress cracks than pure copper due to it being stronger and stiffer.

- Brass is more malleable than copper and is easy to work and cast.

- The melting point of brass is around 900℃, but this may vary depending on the concentration of metals present in the alloy.

- Brass is not ferromagnetic, making recycling much easier.

- By adding different metals to the alloy, brass can display a range of characteristics, such as greater corrosion resistance when manganese is present, or a variable melting point.

Grades of Brass

There are numerous grades of brass, with each having a unique material composition. At Runsom Precision, we offer CNC machining services with six different brass grades:

- Alloy 260, also referred to as cartridge brass. It is a suitable material for creating products such as ammunition, automobiles, fasteners, and hardware due to its ability to withstand cold working.

- Alloy 272, also known as yellow brass and contains 33% zinc. This type of brass is typically utilized in industrial and architectural applications.

- Alloy 330, is a brass alloy ideal for applications requiring high machinability. It contains a low amount of lead, making it optimal for cold-working, and is frequently used in the production of pipes.

- Alloy 353, also called clock brass, is commonly used in the manufacturing of precision components like clock and watch parts due to its outstanding machinability.

- Alloy 360, the most common type of brass, is also known as free cutting brass. This alloy is characterized by its excellent formability and machinability, making it suitable for soldering and brazing operations. It finds widespread application in various fasteners, fittings, valves, and hardware components.

- Alloy 385, also called architectural bronze, is ideal for architectural & construction applications. It comes in an extensive range of extruded and drawn shapes, including handrail molding, angles, square tubes, channels, and more.

- Alloys C48200 to C48500, belong to the category of leaded naval brass suitable for machining. These alloys are typically available in round shapes.

- Alloy 464, also known as naval brass, is highly resistant to corrosion from seawater under broad temperatures. Moreover, it exhibits suitability for welding, bending, hot forming, drawing, soldering, brazing, and heading.

Learn about Our Brass CNC Machining Capabilities

About Copper

Copper is one of the few metals found in nature as a directly usable metallic form. It has an orange-red hue and develops a reddish tarnish when freshly exposed. Unlike brass, it’s a pure metal that can be processed without any artificial manufacturing. Moreover, it can be utilized on its own or combined with other pure metals and alloys to make its subset of alloys.

Copper is extensively utilized as a conductor of heat and electricity, a building material, and a composition of different metal alloys, including cupronickel commonly employed in the manufacturing of coins and marine hardware, constantan used in strain gauges and thermocouples for temperature measurement, and sterling silver utilized in jewelry.

Properties of Copper

Copper possesses various qualities that make it well-suited for construction and manufacturing purposes, including:

- Due to its exceptional thermal and electrical conductivity, copper is a suitable material for use in thermal equipment and electronic and electrical systems.

- Copper showcases resistance to multiple forms of damage, such as impact, wear, and corrosion, while retaining its strength when drawn, formed, and flexed.

- Copper is resistant to bacteria and does not degrade. Moreover, it has the ability to kill bacteria when exposed to its surface. This quality makes it an excellent option for use in equipment intended for food safety.

Grades of Copper

The versatility of copper is enhanced by its availability in various grades. At Runsom Precision, we provide a range of copper grades for the CNC machining process, including:

- Alloy 101 – If manufacturers require high conductivity and ductility, they can choose alloy 101 – a type of oxygen-free copper.

- Alloy 110 – A copper alloy that possesses excellent electrical and thermal conductivity, as well as ductility and malleability. It’s also called electrolytic (ETP) copper.

- Alloy 122 – It shares similarities with Alloy 110 in terms of mechanical properties, but it further offers superior weldability, formability, and brazing capabilities.

- Alloy 145 – or tellurium copper, contains 0.4-0.7% tellurium. It also has exceptional thermal and electrical conductivity, formability, and machinability, and comes in rod and bar forms.

Learn about Our Copper CNC Machining Capabilities

A Complete Comparison of Brass and Copper

The section is to draw attention to five significant areas in which copper and brass can be compared.

Brass VS Copper: Material Properties Differences

1. Composition

Brass and copper can be distinguished by their element compositions. Copper is a pure element with high electrical conductivity, while brass is an alloy of copper and zinc with a variable composition. Brass generally contains 55% – 95% copper and 5% – 45% zinc. The exact composition of brass can vary depending on the intended application and the desired characteristics of the material.

2. Corrosion Resistance

Brass is generally more corrosion resistant than copper due to the addition of zinc. Zinc helps to create a protective barrier on the surface of the metal, which helps to prevent the metal from corroding.

Copper, on the other hand, may corrode in certain environments, especially in the presence of moisture and other substances. Over time, copper can develop a greenish-blue patina on its surface, which may offer some added protection against further corrosion. However, this patina may also be unsightly or interfere with electrical conductivity in some applications.

3. Hardness

Brass is generally harder than pure copper due to the addition of zinc which makes the alloy stronger. The exact hardness can vary depending on the specific composition of the brass and copper being compared. In general, brass has a hardness of around 80-90 on the Brinell hardness scale, while pure copper has a hardness of around 35-45. However, there are also specialized copper alloys like beryllium copper which are harder than brass. Overall, brass is typically considered to be a harder material than pure copper.

4. Weight

When considering the weight of copper and brass, it’s important to note that copper is denser with a density of 8930 kg/cu.m, while brass can vary in density depending on its elemental composition, ranging from 8400 to 8730 kg/cu.m. Based on this, if you require a lightweight metal for your project, you’re supposed to choose brass over copper.

5. Durability

Brass is generally more durable than copper. This is because brass is an alloy made from copper and zinc, which makes it stronger and harder than pure copper. Conversely, copper is softer and more malleable than brass, making it easier to work with in certain applications.

6. Machinability

Brass generally has better machinability than copper due to its higher ductility. Brass has a lower melting point than pure copper, which makes it easier to machine. Additionally, brass has a more uniform and consistent grain structure than copper, which can reduce the occurrence of tool wear and surface roughness during machining.

However, the machinability of both brass and copper can be influenced by the specific alloys and composition of the material, as well as the type of machining process being used. In general, brass is often preferred over copper in applications where machinability is a primary concern.

7. Weldability

Welding of copper is easier when it is oxygen-free or deoxidized. Copper can be welded using MIG and TIG techniques, and brass alloys support these methods as well as silver soldering. However, lead-containing alloys are more challenging to weld, while alloys with lower zinc content are easier to weld.

The following table concludes a comparison of the material characteristics of brass and copper:

| Properties | Copper | Brass |

| Composition | Copper | Primary: Copper & Zinc Others: Iron, Lead, Aluminum, Silicon, Manganese, etc. |

| Machinability | Moderate | High |

| Weldability | High | Low |

| Durability | Durable | Highly durable |

| Weight | 8930 kg/cu.m | 8400 to 8730 kg/cu.m |

| Corrosion Resistance | Good | Excellent |

Brass VS Copper: Conductivity Differences

1. Electrical Conductivity

Both brass and copper are good conductors of electricity, but copper has a higher electrical conductivity than brass. In applications where high conductivity is essential, such as in electrical wiring, copper is preferred over brass. However, brass is still a widely used material in electrical components due to its other desirable properties such as corrosion resistance and machinability.

2. Thermal Conductivity

Brass and copper are both excellent thermal conductors, but copper has a higher thermal conductivity compared to brass. The thermal conductivity of copper ranges from 385 to 410 W/mK, while brass has a thermal conductivity ranging from 109 to 141 W/mK. This means that copper is more effective at conducting heat than brass.

Brass VS Copper: Their Ability to Form

1. Melting Point

When formability is required for a project, comparing the melting points of copper and brass can help to select which metal is the more suitable. The melting point of copper is 1083°C (1981°F), while brass alloys have a melting range between 900°C (1650°F) and 940°C (1720°F), depending on the composition. Therefore, brass has a lower melting point than pure copper due to the presence of zinc in its structure.

2. Formability

Brass is generally more formable than copper due to its lower melting point and higher malleability. Brass can be rolled, drawn, or stamped into complex shapes with relative ease, making it a popular choice for decorative and functional applications. Copper, on the other hand, is typically more brittle than brass, which can make it more difficult to form precise shapes without cracking or breaking.

Brass VS Copper: Strength Differences

1. Yield Strength

The point at which a material starts to deform permanently, known as the yield strength, is generally considered the highest stress it can handle. When comparing copper and brass, it can be seen that brass has a higher yield strength than copper.

2. Tensile Strength

Compared to copper, brass is more rigid and durable, which also makes it more vulnerable to stress fractures. Although the ultimate tensile strength of brass is lower, it can be improved by altering the elemental composition. Brass generally has a higher tensile strength than pure copper. The tensile strength of brass typically ranges from 338-469 MPa, while pure copper has a tensile strength of around 210 MPa.

Brass VS Copper: Appearance and Price Differences

1. Color

Copper and brass are two different materials, with copper being a pure metal and brass being an alloy of copper. The color of copper is usually distinct, with its reddish-brown hue making it easy to distinguish from brass. Brass, on the other hand, can come in various colors, such as golden yellow, reddish-gold, or silver, depending on its elemental components.

2. Price

The cost of brass and copper can fluctuate based on the specific grades being compared. Generally, copper tends to be the pricier option between the two. Brass, on the other hand, has a lower copper content, which makes it less expensive.

Brass & Copper: Their Applications

Although copper and brass share some common applications, there are notable differences between the two. Below are some significant uses of these metals:

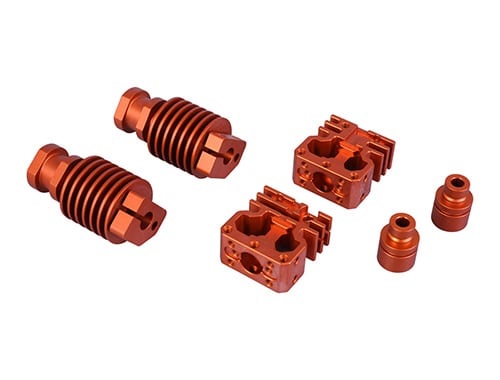

Applications of Brass

Brass is widely known for its decorative and aesthetic benefits, as well as its versatility and workability. Due to these properties, it has found applications in various industries. Some of the uses of brass are:

- Locks

- Hinges

- Valves

- Fittings

- Bearings

- Ammunition casings

- Plumbing and piping materials

- Hose couplings

- Electrical plugs and sockets

- Electronics and electrical terminals

- Musical instruments

- Clock and watch components

Applications of Copper

Copper possesses various advantages, such as outstanding conductivity and weldability. Therefore, it’s commonly used in diverse applications, including:

- Roofing

- Plumbing

- Electrical wiring

- Vacuum tubes

- Electric motors

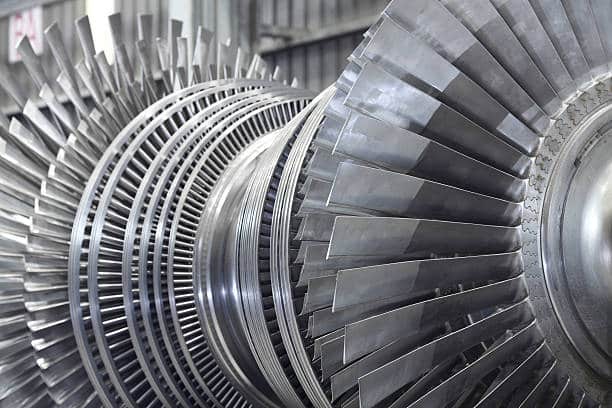

- Heat sinks and heat exchangers

- Industrial machinery

- Architectural components

- Telecommunication components

- Anti-biofuel components in submarines

Tips for Choosing the Right Material For Your Projects

When it comes to designing and manufacturing high-quality parts or products, selecting the appropriate metal is crucial. Copper and brass, both known for their electrical and thermal conductivity, corrosion resistance, and strength, have distinct differences that must be considered. As you choose your sheet metal materials, keep in mind some of the essential differences between these two metals:

- Brass and copper, though durable in nature, differ in their levels of flexibility. Copper with pure oxygen-free content is the most flexible with high ductility and conductivity. While copper boasts excellent conductivity properties, brass has greater machinability.

- For general purposes, brass is commonly preferred due to its versatile nature. If cost is a significant factor, then it may be preferable to choose brass over copper because brass is less expensive. Nevertheless, if you require electrical conductivity, copper would be advantageous.

Conclusion

Being aware of the difference between brass and copper can help you in learning the distinctive qualities of each material and in selecting the appropriate sheet metal for your rapid prototyping or any project. The choosing process is crucial to achieving superior outcomes during the design and production phases. We hope that this page will offer you some useful knowledge for your selection and we emphasize that both metals have significant value in their respective applications, therefore neither one is definitively superior to the other.

Metal Machining and Prototyping – Count on Runsom Precision

Work with Runsom Precision for metal material selection and gaining a competitive edge. We have skilled technicians and machinists who can choose the best material for your project. Moreover, we offer manufacturing and prototyping services such as CNC machining, sheet metal fabrication, and 3D printing. Choose us as your brass and copper parts manufacturer and get started with an instant quote and DfM analysis today!

Other Articles You May be Interested in: