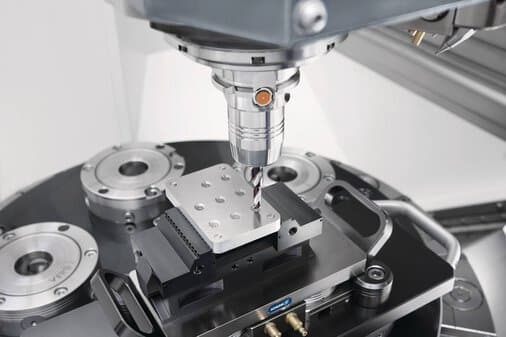

Obstruction-Free Machining with Our 5-Axis Workholding Systems

Runsom Precision provides a comprehensive range of 5-axis clamping solutions designed to deliver exceptional clamping force in conjunction with 5-axis machinery.

We are dedicated to providing quality workholding products and custom solutions using our latest CNC machining technology. We provide 5-axis vises and accessories, single station vises, modular vises, towers, tombstones, and a variety of other options, ensuring that you can find the perfect workholding product for your specific application.

Our 5-axis workholding vises are specifically engineered to facilitate obstruction-free machining on all five sides of a workpiece. They offer the added advantage of rapid, single clamp setup and enable continuous, high-speed milling of pockets and intricate 3-dimensional surfaces.

If you're uncertain about which vise is best suited for your application, reach out to us today to obtain the precise workholding solution you require.

5-Axis Workholding Systems

The 5-axis workholding system is specifically designed to cater to "true" 5-axis complete/simultaneous machining needs. Although primarily developed for multi-axis CNC milling, these solutions also bring benefits to common 3-axis CNC machining tasks and even 2-axis CNC turning operations.

Our versatile product range enables users to apply this technology across various applications, including palletized 4-axis horizontal CNC mills with tombstones, 5-axis CNC machines, and CMM fixtures.

Self Centering Vise

True Self-Centering Functionality

Attain certainty in repeatability through extremely tight tolerances.

Self-centering vises can center workpieces with exceptional precision while preserving a compact profile and footprint, enabling full access to all five sides of the workpiece.

Encounter exceptional clamping force and accuracy using our self-centering vises. These vises are purpose-built to thrive in multi-axis machining settings. With a distinctive design, each jaw is maneuvered by a left- and right-handed leadscrew, guaranteeing consistent clamping at the center of your raw billet after each rotation. Enhance your machining capabilities with our self-centering vises.

- This system is its automatic adjustment of the workpiece to the center, resulting in enhanced machining precision and repeatability.

- It is compatible for use with either horizontal or vertical machinery.

- This system is particularly advantageous for applications that necessitate high levels of accuracy, such as milling, drilling, and finishing processes.

- It provides a greater clearance angle, facilitating improved chip evacuation during machining operations.

- It boasts a high holding power, further enhancing its utility.

Dovetail Fixtures

Stable, Accessible, and Repeatable Clamping

Minimize part deformation and optimize stock usage.

Dovetail clamps employ downward force, rather than lateral pressure, to evenly distribute clamping force across the workpiece, while the precise locating pin guarantees the centering of your part in the fixture. Mechanically locking your workpiece through dovetailing enhances stability, reduces torque requirements, and is ideal for compact workholding and precise repeatability.

Achieve exceptional strength in a condensed design with dovetail fixtures. Tailored for 4 and 5-axis machining operations, our dovetail fixtures epitomize robustness and stability. Enhance your machining accuracy with the unmatched rigidity provided by our dovetail fixtures.

- This system enables multiple parts to be secured by distinct jaws and machined using a single centering dovetail vise.

- With the aid of a locating pin, all parts can be clamped and positioned uniformly, simplifying part loading and unloading even with minimal training required.

- It is offered in various sizes and jaw styles to accommodate and secure parts of all dimensions. These work holding devices can be directly mounted on a machine pallet for horizontal or vertical machining, or on a tombstone.

- It reduces distortion in machined parts caused by clamping forces.

Multi-Fixture Mounts

Boost productivity with minimal space requirements.

Multi-fixture mounts encompass tombstone- and pyramid-style mounts that serve as excellent additions to compact 3-, 4-, and 5-axis machine setups.

With our pyramid workholding solutions, you can significantly increase your component production on your 5-axis machine, tripling your output. Whether handling extensive repetitive part runs or short production cycles, our quick-change patterns simplify tooling swaps, reduce operations, and boost efficiency.

- Tombstones commonly referred to as pedestal fixturing, tooling towers, or fixture blocks, typically feature four sides for direct attachment of parts or fixture plates and present a swift and accurate solution for tooling changeovers.

- A pyramid riser facilitates the loading of multiple parts per fixture, increasing the productivity of a 5-axis machine. This enables greater throughput for smaller or less intricate workpieces.

Workpiece Options

Cylinder

(Small diameters)

Square

Dovetail

Rectangular

Cylinder

(Large diameters)

Enhance the Efficiency of your 5-Axis Machining Center with Rigid and Highly Accurate Workpiece Clamping Systems

When it comes to 5-axis clamping solutions, Runsom Precision stands out as your premier choice. We'll work with you to identify the optimal workholding option to meet your specific needs.

When using our 5-axis workholding system, you can expect ample clamping force to secure and stabilize intricate or irregularly shaped components. Our 5-axis workholding facilitates unobstructed machining on all five sides of a workpiece. If your equipment requires tackling challenging angles and intricate shapes, our 5-axis workholding is designed to deliver. Our 5-axis solutions feature a simple and time-efficient clamp setup, tailored to support continuous, high-speed machining of pockets and complex 3-dimensional surfaces. Operating with precision, our product effectively reduces customers' tooling and labor costs.

Our manufacturing capabilities are specialized to meet the unique requirements of our clients. What you need is a blend of knowledge, expertise, and dedication. Contact our team of experts or request an instant online quote to discuss your machining needs and receive custom-tailored solutions.